Introduction

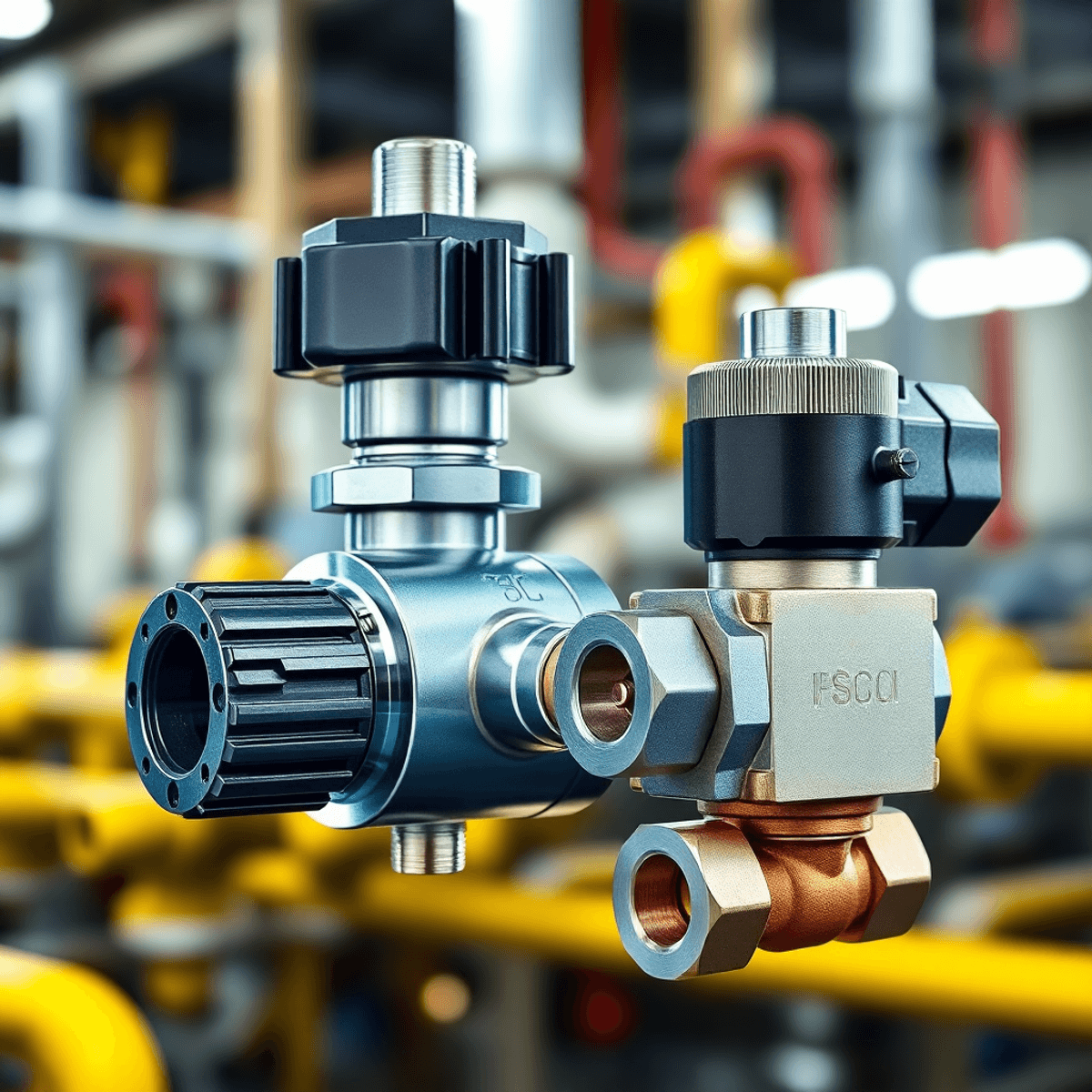

Pressure regulators and solenoid valves are critical components in industrial applications. They play a crucial role in managing fluid dynamics and ensuring operational safety.

- Pressure Regulators: These devices maintain a consistent outlet pressure, which is vital for efficient system performance. They prevent pressure fluctuations that can lead to equipment damage or inefficient processes.

- Solenoid Valves: These electrically controlled valves manage the flow of fluids with precision, allowing for automated control in various systems.

The combination of pressure regulators and solenoid valves offers numerous advantages:

- Enhanced operational efficiency

- Reduced energy consumption

- Improved safety measures

In this article, we will explore how integrating these two technologies can significantly enhance industrial efficiency. Understanding their functionalities and synergies will provide insights into optimizing your industrial operations. By examining their roles across various applications, you will gain valuable knowledge to implement these solutions effectively in your processes.

Understanding Pressure Regulators and Solenoid Valves

Pressure regulators and solenoid valves are essential components in industrial settings, playing vital roles in pressure control and fluid control systems.

Definition and Function

Pressure Regulators

These devices maintain a predetermined outlet pressure regardless of fluctuations in the inlet pressure. They ensure that processes operate within safe and efficient pressure ranges.

Solenoid Valves

These electrically operated valves control the flow of liquids or gases within a system. When energized, the solenoid coil creates a magnetic field that opens or closes the valve, enabling precise fluid control.

Importance of Stable Outlet Pressure

Maintaining stable outlet pressure is crucial for:

- Ensuring consistent product quality

- Preventing equipment damage from overpressure

- Enhancing the efficiency of processes by reducing energy consumption

Types of Pressure Regulators

- Single-stage Regulators: Designed for applications where inlet pressure does not fluctuate significantly. They offer quick response times but may not maintain stability under varying conditions.

- Two-stage Regulators: Ideal for applications requiring more accurate pressure control. The first stage reduces the high inlet pressure to an intermediate level, while the second stage fine-tunes it to the desired outlet pressure.

- Electronic Pressure Regulators: Utilize electronic sensors and actuators for precise control, allowing real-time adjustments based on system demands.

Solenoid Valve Types

Understanding solenoid valve types enhances their application potential:

- 2-way Valves: Control flow through two ports; ideal for simple on/off operations.

- 3-way Valves: Offer three ports to redirect flow, useful in diverting applications or mixing different fluids.

- Direct-acting Valves: Operate using electromagnetic force directly on the valve seat; suitable for low-pressure applications.

- Indirect-acting Valves: Use pilot pressure to operate; well-suited for high-flow and high-pressure systems.

The synergy between these components fosters improved operational efficiency, laying a foundation for enhanced industrial performance.

The Synergy Between Pressure Regulators and Solenoid Valves

Pressure regulators and solenoid valves create a powerful combination in industrial settings, enhancing fluid dynamics and process management. Their collaboration ensures precise fluid control, which is critical for maintaining operational efficiency.

Working Together

Fluid Control

- Pressure regulators maintain stable outlet pressure

- Solenoid valves act as on/off switches or flow controllers

This synergy allows for:

- Accurate flow rates

- Responsive adjustments to changing conditions

- Enhanced safety by preventing overpressure situations

Process Management

The integration of both technologies streamlines operations. Examples include:

- Automated systems that respond to pressure changes in real time

- Reduced manual intervention, minimizing human error

Benefits of the Combination

Integrating pressure regulators with solenoid valves leads to significant advantages, such as:

- Improved Efficiency: Reduced energy consumption through optimized flow control.

- Cost Savings: Minimizing wastage of resources and lowering maintenance costs due to fewer system failures.

- Increased Longevity: Better management of pressure fluctuations extends the lifespan of equipment.

This combination not only enhances operational efficiency but also fosters reliability in various industrial applications, making it an essential element in modern automation.

Real-world Applications Across Industries

Pressure regulators and solenoid valves are essential in many industries, ensuring smooth and dependable operations. Here’s a look at the sectors that use these technologies:

1. Manufacturing Automation

Accurate control of fluid flow is crucial for machinery operation. Pressure regulators maintain optimal pressure levels, while solenoid valves enable quick on/off control, enhancing production efficiency.

2. Chemical Processing

In this industry, maintaining consistent pressure is vital for safety and product quality. Pressure regulators manage outlet pressure during reactions, while solenoid valves control the flow of hazardous materials, minimizing risks.

3. Food Processing

Hygiene and accuracy are paramount in food applications. Pressure regulators ensure that processing equipment operates within safe pressure ranges. Solenoid valves facilitate the precise dispensing of liquids, contributing to product consistency.

4. HVAC Systems

In heating and cooling applications, managing air and fluid flow is critical. Pressure regulators help maintain desired pressures in duct systems. Solenoid valves enable efficient control of refrigerants and hot water circulation.

The use of pressure regulators and solenoid valves not only makes processes smoother but also improves safety and productivity in these diverse industries.

Texas Industrial Remcor: A Leader in Valve Technology

Texas Industrial Remcor has established itself as a prominent player in the valve manufacturing industry since its inception in 1972. This family-owned business, located in Little River Academy, Texas, has built a reputation for integrity and competitive pricing. With decades of experience, they specialize in various valve solutions tailored for multiple sectors including agriculture, automotive, landscaping, and HVAC systems.

Key highlights of Texas Industrial Remcor include:

- Specialization in Sprayer Valves: Known for developing high-quality sprayer valves that effectively manage fluid control applications. These valves are crucial in industries requiring precise regulation.

- Advanced Control Systems: The company offers sophisticated control systems that integrate seamlessly with pressure regulators and solenoid valves. This synergy enhances operational efficiency and reliability.

- Commitment to Quality: Texas Industrial Remcor focuses on engineering perfection into every product. Their attention to detail and smart technology ensures long-lasting performance that meets the rigorous demands of various industries.

With a strong foundation and commitment to innovation, Texas Industrial Remcor continues to make significant contributions to the valve manufacturing landscape, positioning itself as a trusted partner for American and international companies alike.

Future Trends in Industrial Automation Technologies

The world of industrial automation is changing quickly. New trends are transforming how industries handle fluid and air regulation solutions. Here are some important developments to watch for:

1. Smart Technology Integration

IoT devices are being integrated into pressure regulators and solenoid valves, enabling real-time monitoring and control. This connectivity improves operational efficiency by providing data-driven insights.

2. Artificial Intelligence

AI algorithms are increasingly being used to predict system failures and optimize performance. Predictive maintenance reduces downtime and extends the lifespan of equipment.

3. Energy Efficiency Focus

There is a growing emphasis on energy-efficient solutions. Manufacturers are developing advanced pressure regulators and solenoid valves that minimize energy consumption while maintaining performance standards.

4. Customization and Modular Solutions

Industries require more customized solutions. Manufacturers are responding by offering adaptable pressure regulation systems that can be easily integrated into existing operations.

5. Sustainability Initiatives

A shift towards sustainable practices influences product design. Companies are prioritizing eco-friendly materials and energy-efficient technologies, aligning with global sustainability goals.

These future trends indicate a more connected, efficient, and sustainable industrial environment where pressure regulators and solenoid valves play a vital role in driving innovation and operational excellence.

Conclusion

Pressure regulators and solenoid valves are essential for improving industrial efficiency. They ensure stable outlet pressure and control fluid dynamics, which are crucial for smooth operations in various industries.

Key points to consider:

- Importance of regulation technologies: These components ensure precision and reliability in processes, reducing downtime and operational costs.

- Benefits of implementation: Utilizing pressure regulators and solenoid valves can lead to significant improvements in productivity and safety.

As you evaluate your own applications, think about how these technologies could impact your operations. Whether in manufacturing, chemical processing, or HVAC systems, integrating pressure regulators and solenoid valves can bring substantial benefits.

Take action now to enhance your industrial efficiency. Look for solutions that are tailored to your specific needs and explore how regulation technologies can optimize your processes. Embrace the potential of these crucial components for a more efficient future.